|

个人信息Personal Information

副教授

硕士生导师

教师拼音名称:Zhou Kun

电子邮箱:

入职时间:2020-09-01

所在单位:高端装备机械传动全国重点实验室

学历:研究生(博士)毕业

性别:男

联系方式:zhoukun@cqu.edu.cn

学位:工学博士学位

在职信息:在职

毕业院校:西南交通大学

-

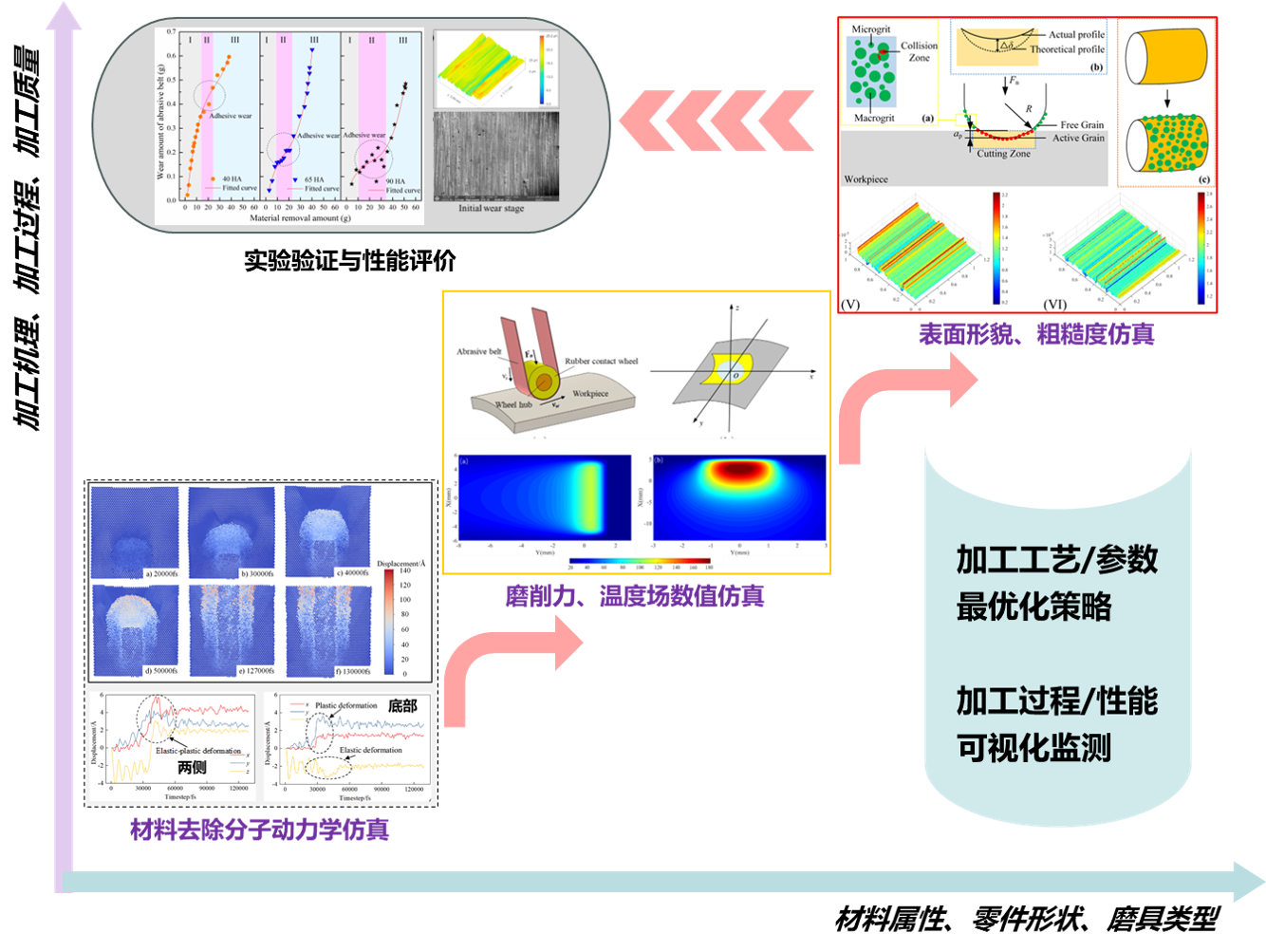

1. 磨削材料去除机理、表面完整性与工艺优化研究

针对航空航天、轨道交通等领域的钛合金、高温合金、复合材料复杂曲面零部件难加工问题,利用分子动力学、有限元、数值仿真等方法开展磨削材料去除机理和表面完整性建模仿真研究,基于全寿命周期实验阐明超硬磨粒磨损行为及其对加工质量的影响规律,综合运用无损检测、图像识别、深度学习等方法进行磨削过程智能监测和工艺/参数优化。

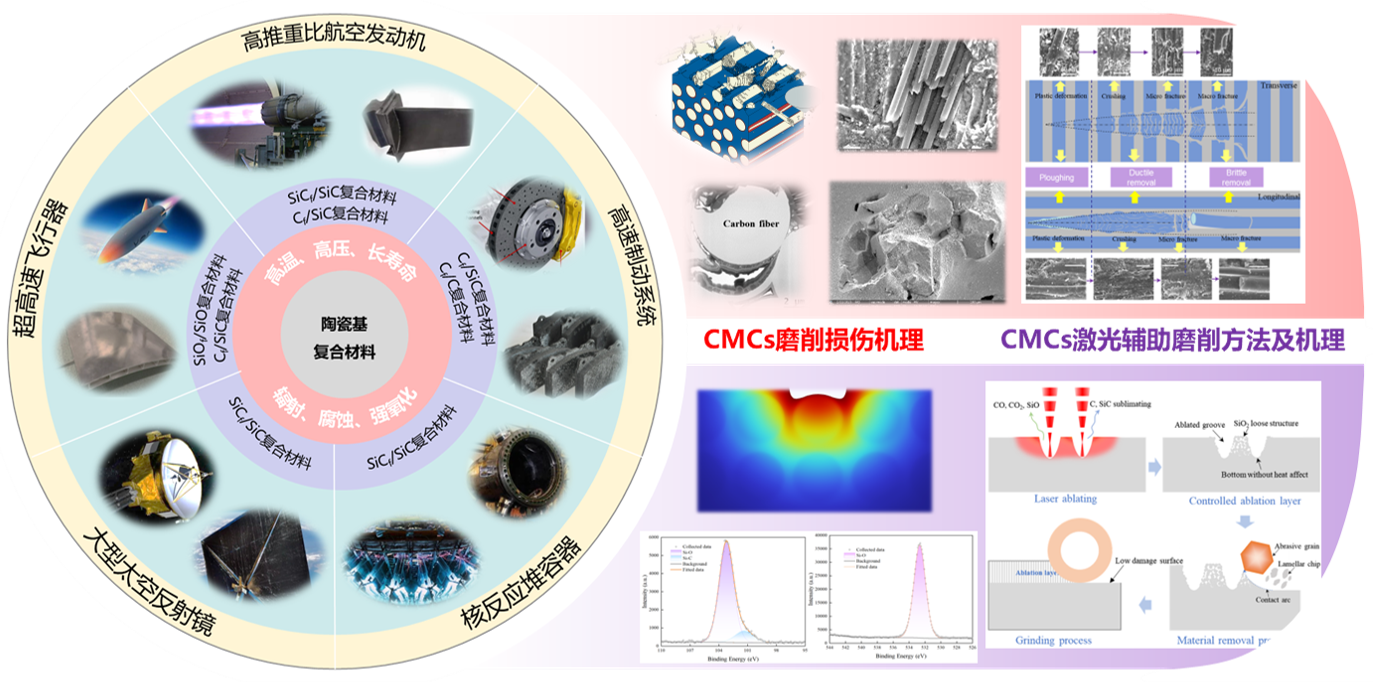

2. 陶瓷基复合材料磨削损伤与激光辅助磨削研究

面向下一代高推重比航空发动机等关键零部件对陶瓷基复合材料的重大需求,针对制约其高性能服役的难加工问题,开展磨削损伤形成机理与智能检测研究,提出基于激光诱导可控烧蚀辅助磨削的高效、低损伤、低磨损加工方法,显著降低了磨削力、磨削温度、磨粒磨损、表面粗糙度和表面/亚表面损伤。

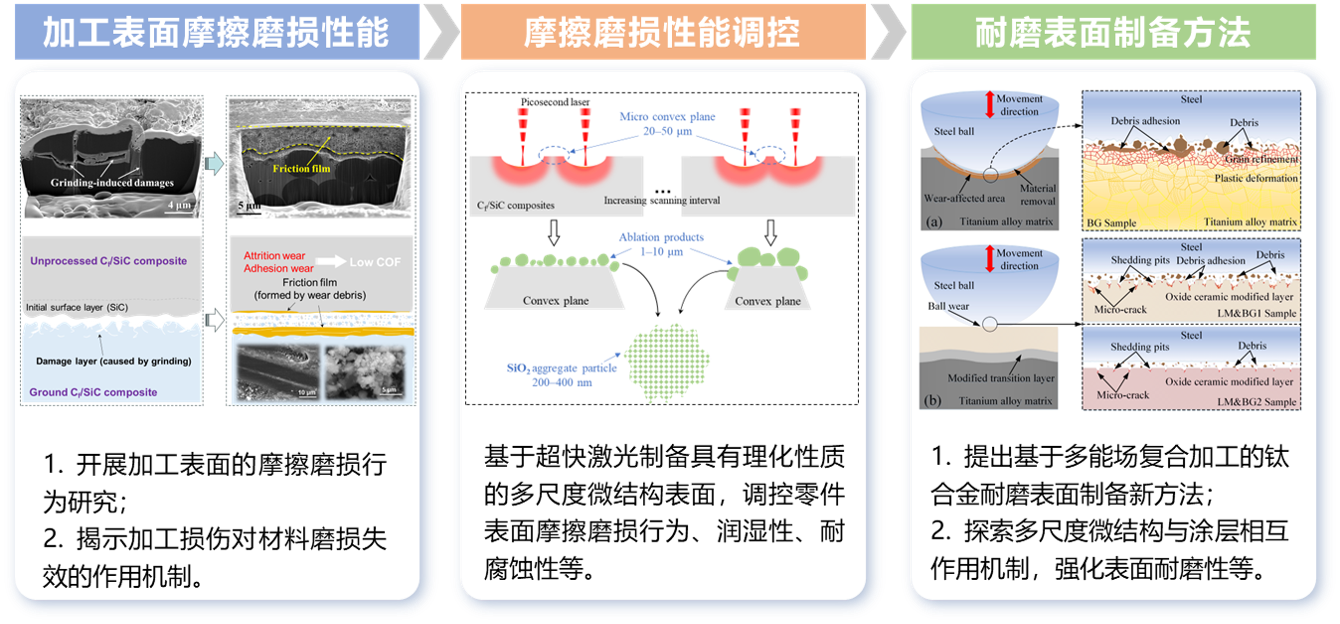

3. 加工表面的摩擦磨损行为及耐磨性提升方法研究

研究旨在建立材料加工表面影响层与其摩擦磨损行为之间的关系:(1)阐明了陶瓷基复合材料磨削诱导多类型损伤对摩擦磨损行为的影响规律;(2)提出了基于超快激光烧蚀多尺度微结构表面的摩擦磨损行为调控方法;(3)提出了基于激光磨削复合加工的钛合金超耐磨比表面制备方法。

- Surface integrity during rail grinding under wet conditions: Full-scale experiment and multi-grain grinding simulation:Tribology International

- ,.A novel low-damage and low-abrasive wear processing method of C-f/SiC ceramic matrix composites: Laser-induced ablation-assisted grinding:JOURNAL OF MATERIALS PROCESSING TECHNOLOGY,302:-

- ,,,.A Study on Aerodynamic Performance of Different Bionic-Structured Surfaces via Belt Grinding:JOURNAL OF BIONIC ENGINEERING,2021,18:1179-1191

- 肖贵坚,,.Material removal behavior of C-f/SiC ceramic matrix composites as a function of abrasive wear during diamond abrasive belt grinding:WEAR,2021,486:-

- 肖贵坚,,,,,.Probing residual stress evolution of titanium alloy due to belt grinding based on molecular dynamics method:JOURNAL OF MANUFACTURING PROCESSES,2021,66:446-459

- ,,,,.Temperature field and material response as a function of rail grinding parameters:INTERNATIONAL JOURNAL OF HEAT AND MASS TRANSFER,2021,175:121366

- 暂无内容

- 暂无内容

- 暂无内容